A collaboration between ESSIC, supply-chain-mapping company Resilinc, and the University of Maryland’s Supply Chain Management Center was recently published in Harvard Business Review. ESSIC scientist Michael Gerst is second author on this paper.

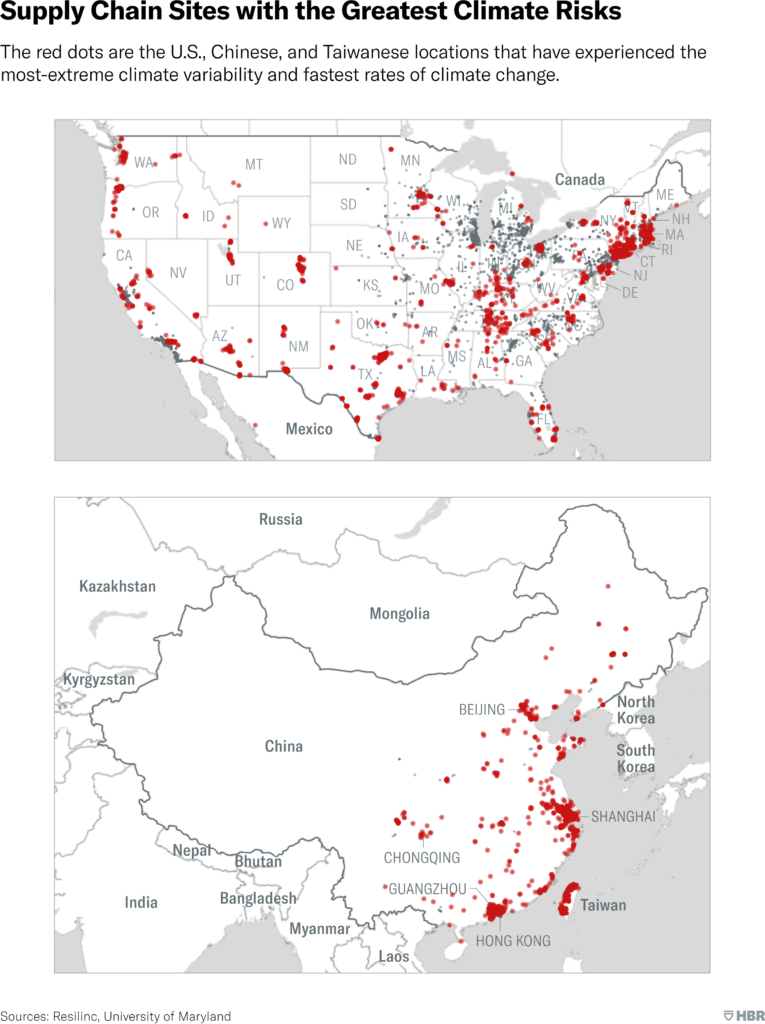

In the study, the researchers analyzed the supply chains of 100 original equipment manufacturers (OEMs) in the high tech, auto, and consumer goods industries. These OEMs either directly owned or outsourced to 12,000 U.S., Chinese, and Taiwanese production sites in our sample. For each site’s latitude and longitude, they collected temperature and precipitation data. They measured climate variability over time and connected this data to Resilinc-collected site data about business impacts, the availability of backup manufacturing sites, the existence of a business continuity plan, and how long it would take the site to recover if disrupted by an extreme climate-related event.

The analysis found that 49% of the sites in the United States, China, and Taiwan (in red) experienced an increase in climate variability, with the proportion much higher in China and Taiwan (93%) than in the U.S. (33%). Nearly all the sites in China had experienced an increase in heat waves. This intensification of extreme climate events is consistent with the findings of IPCC reports.

The researchers also found that most companies are ill-prepared for climate-related disruptions, and offer several measures that can be implemented to minimize these coming risks.

Gerst is a research faculty at the Earth System Science Interdisciplinary Center at the University of Maryland. His scientific work is motivated by helping stakeholders identify problems and solutions at the intersection of the environment, technology, and society. As a result of the complexity of these issues, his approach is rooted in systems, data, and decision science, which together allow for a holistic understanding of current knowledge so that stakeholders may assess trade-offs and risks of potential solutions. Dr. Gerst’s research portfolio has ranged from participatory development of global change indicators, cost-benefit analysis under uncertainty, life-cycle analysis, and scenario planning to designing and testing the efficacy of visualizations. His application areas have spanned climate change mitigation, food-energy-water nexus, critical materials, healthcare systems, and corporate sustainability.

To read the article, click here: “How Exposed Is Your Supply Chain to Climate Risks?”.